Introduction

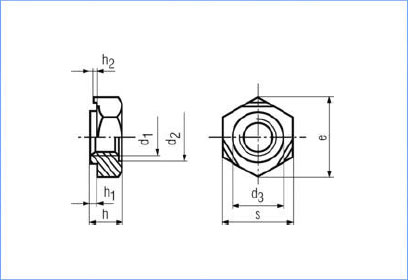

DIN 929

A projection nut is a type of fastener that is designed to be mounted onto a workpiece using a projection welding process. It is typically made of steel or another metal, and has a small, cylindrical head with a threaded hole in the center. Projection nuts are used in a variety of applications, including automotive manufacturing, construction, and appliance production. They are commonly used to attach components to a metal surface, and can be mounted in place using a projection welding process, which involves applying pressure and electrical current to the nut and workpiece at specific points called projections. Projection nuts offer several advantages over other types of fasteners, including high strength, corrosion resistance, and the ability to withstand high temperatures. They are often used in applications where it is necessary to maintain a smooth surface or to allow for the passage of fluids or other materials through the nut.

All measurements in millimeters (mm)

| D1 | D2 H13 | D3 d11 | H1 | H2 | H H14 | S H13 | Sheet Thickenss | Proof Load N | |||

| MIN | MAX | ||||||||||

| M3 | 4.5 | 4.5 | 0.55 | 0-0.1 | 0.25 | 0-0.1 | 3 | 7.5 | 0.63 | 2.6 | 3800 |

| M4 | 6 | 6 | 0.65 | 0.35 | 3.5 | 9 | 0.75 | 3 | 6800 | ||

| M5 | 7 | 7 | 0.7 | 0.4 | 4 | 10 | 0.88 | 3.5 | 11000 | ||

| M6 | 8 | 8 | 0.75 | 0-0.15 | 0.4 | 5 | 11 | 0.88 | 4 | 15500 | |

| M8 | 10.5 | 10.5 | 0.9 | 0.5 | 0-0.15 | 6.5 | 14 | 1 | 4.5 | 28300 | |

| M10 | 12.5 | 12.5 | 1.15 | 0-0.2 | 0.65 | 8 | 17 | 1.25 | 5 | 44800 | |

| M12 | 14.8 | 14.8 | 1.4 | 0.8 | 0-0.2 | 10 | 19 | 1.5 | 5 | 65300 | |

| M14 | 16.8 | 16.8 | 1.8 | 1 | 11 | 22 | 2 | 6 | 89700 | ||

| M16 | 18.8 | 18.8 | 1.8 | 1 | 13 | 24 | 2 | 6 | 123000 | ||