Introduction

A contact washer is a type of washer that is designed to provide a secure hold and reduce friction between two surfaces. It is typically made of a flexible material, such as spring steel or plastic, and has a conical or tapered shape. The tapered shape allows the washer to compress slightly when it is tightened down, creating a spring-like action that helps to maintain a constant pressure on the fastener and the material being fastened. This helps to prevent loosening due to vibration or torque and can also reduce wear on the fastener and the surrounding components. Contact washers are often used in applications where a secure hold is necessary, such as in the assembly of engines, gearboxes, and other mechanical components. They can also be used in electrical and electronic applications to help prevent the loosening of terminal connections.

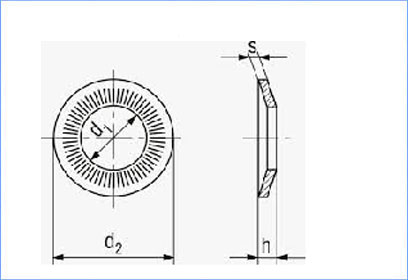

Dimension Table for Contact Washers

| Contact Washer As Per Din SN 70093 | |||||||||

| Part Code | Dia | INNER DIA (D1) | OUTER DIA (D2) | THICKNESS (S) | HIGHT (H) | ||||

| MIN | MAX | MIN | MAX | MIN | MAX | MIN | MAX | ||

| MCOW03000 | M3 | 3.10 | 3.35 | 5.80 | 6.20 | 0.57 | 0.63 | 0.80 | 0.95 |

| MCOW04000 | M4 | 4.10 | 4.40 | 7.80 | 8.20 | 0.77 | 0.83 | 1.00 | 1.15 |

| MCOW05000 | M5 | 5.10 | 5.40 | 9.80 | 10.20 | 0.97 | 1.03 | 1.25 | 1.50 |

| MCOW06000 | M6 | 6.10 | 6.40 | 11.80 | 12.20 | 1.16 | 1.24 | 1.50 | 1.80 |

| MCOW08000 | M8 | 8.20 | 8.50 | 15.80 | 16.20 | 1.36 | 1.44 | 1.95 | 2.40 |

| MCOW10000 | M10 | 10.20 | 10.56 | 19.75 | 20.25 | 1.56 | 1.64 | 2.15 | 2.60 |

| MCOW12000 | M12 | 12.40 | 12.80 | 23.75 | 24.25 | 1.56 | 1.64 | 2.15 | 2.60 |

| MCOW14000 | M14 | 14.40 | 14.83 | 23.75 | 24.25 | 1.56 | 1.64 | 2.05 | 2.50 |

| MCOW16000 | M16 | 16.40 | 16.80 | 31.70 | 32.30 | 2.44 | 2.56 | 3.50 | 3.95 |

| MCOW20000 | M20 | 20.50 | 21.00 | 39.70 | 40.30 | 2.94 | 3.06 | 4.20 | 4.65 |